Twenty-five years ago Westfall made a simple orifice mixer—a plate with a small round hole and an injection port. Today Westfall’s high shear static mixers feature a sophisticated geometric opening with bent tabs that create rapid turbulence within a limited lay length.

This new breed of high performance static mixer is increasingly chosen by engineers around the world, because of the high shear performance, low cost, low maintenance and ease of installation.

Models Available

- Compact 2800

- Inline 2850

- Variable Flow 2900

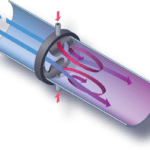

Compact High Shear Model 2800

For complete and efficient short lay length pipeline mixing. Westfall’s high shear static mixer has a slim profile which allows simple drop-in installation in pipelines from 2″ to 120″. Alternate vortex shedding creates high performance mixing within a limited space. This is a full pipe motionless mixer into which up to six additives can be injected simultaneously or in specifically timed stages. High shear mixing also creates micro-bubbles for effective removal of salt from oil or oil from water. Where space is limited, this affordable static mixer is ideal for municipal and regional infrastructure upgrades. It is available with a wide range of injection ports and quills, and a choice of 3 aperture sizes: .7 BETA, .8 BETA and .9 BETA.. The mixer resists fouling and requires little to no maintenance.

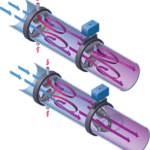

Inline Static Mixer 2850

An inline static mixer that resists plugging from calcium build up. The Inline Static Mixer Model 2850 is the ideal replacement for plugged up mixers. A common problem with conventional static mixers is that, when caustics are added, calcium deposits build up on the mixer and block the flow of liquids. This inline static mixer offers a high performance solution that improves mixing and resists calcium build up. The plate’s singular orifice, with cloverleaf-shaped tabs, generates high-shear mixing. Moving the injection port 1/2 diameter downstream in the pipe from the mixer yields a 200% reduction in the concentration of the injected caustic.

Variable Flow Static Mixer Model 2900

For maintaining constant headloss while blending liquids or gases of varying flows, viscosities and temperatures. The compact drop-in Variable Flow Mixer Model 2900 accommodates a turn down ratio of up to 20-1 in liquids or gases by incorporating two of Westfall’s signature plate mixers. The mixer provides a faster, better and often more economic choice for mixing and blending while providing constant headloss. The upstream plate remains stationary while the downstream plate pivots as it adjusts incrementally to changing flow conditions. The downstream mixer responds to a differential pressure controller, opening wide for maximum flow velocity to reduce headloss, and closing as flow decreases to enhance mixing. Headloss remains constant throughout.